Welcome to Shanthala Machining Technologies Pvt Ltd

Global Certificate: ISO 9001:2015

Welcome to Shanthala Machining Technologies Pvt Ltd

Global Certificate: ISO 9001:2015

Our world is a complex interchange of numerous factors. The biological precision that nature requires has been established over millions of years by nature itself. For what man develops, we need man-made precision; otherwise, we could not switch on a light, use a phone or fly by plane. Though more and applications demand micron precision, we do not always need to "split the micron". Sometimes, it is the output of a high-volume production system that counts; at other times, what counts is flexibility. In each and every case, you can rely on our solutions - in every aspect, in its entirety and down to the very last micron.

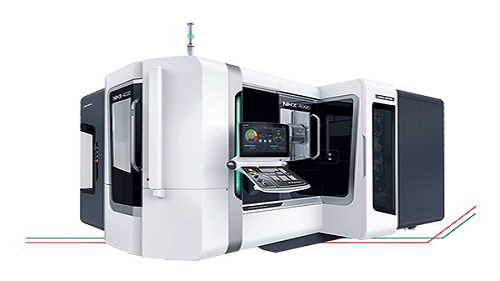

SMTPL is well equiped with the latest machining technologies to cater the precised and high accuracy components to meet our customers requirements.

Horizontal Machining, also known as milling, relies on rotary cutters to remove metal from a workpiece. Horizontal machining occurs on a horizontal machining center (HMC), which employs a spindle that is parallel to the ground floor. With a horizontally oriented spindle, tools stick out of the side of the tool holder and cut across the side of a workpiece, encouraging chips to fall away from the table. Horizontal machining centers also allow for two - pallet changer integration to facilitate unattended operation and reduce part cycle times.

Vertical Machining, also known as milling, relies on rotary cutters to remove metal from a workpiece. Vertical machining occurs on a vertical machining center (VMC), which employs a spindle with a vertical orientation. With a vertically oriented spindle, tools stick straight down from the tool holder, and often cut across the top of a workpiece.

Turning is a machining process used to make cylindrical parts, where the cutting tool moves in a linear fashion while the workpiece rotates. Commonly performed with a lathe, turning reduces the diameter of a workpiece, typically to a specified dimension, and produces a smooth part finish. A turning center is a lathe with a computer numerical control. Sophisticated turning centers can also perform a variety of milling and drilling operations.

A coordinate measuring machine (CMM) is a device that measures the geometry of physical objects by sensing discrete points on the surface of the object with a probe. Various types of probes are used in CMMs, including mechanical, optical, laser, and white light.